Advantages Of Resin Transfer Moulding (RTM) - you were

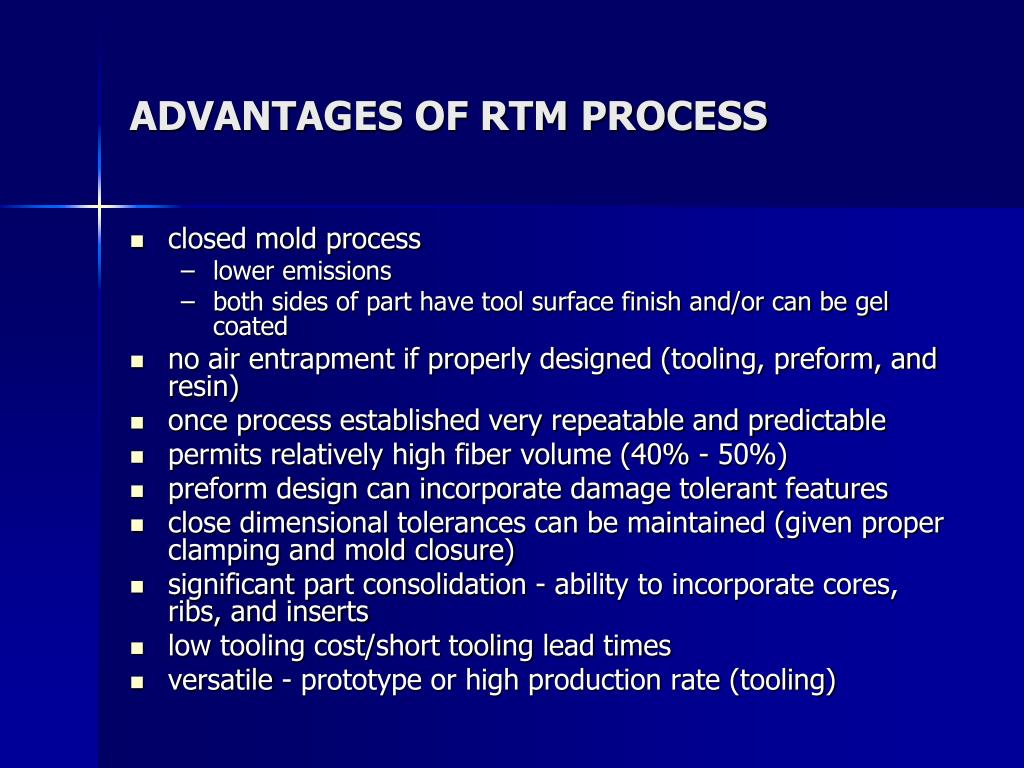

Add Favorite Transfer molding is originally used for the molding of thermosetting polymers. In principle, thermosetting polymer charge is prepared in a container and transferred to closed molds by hydraulic rams. Inside these closed molds, the curing of thermosetting takes place. To produce polymer matrix composites, some adjustments are made in the conventional transfer molding process, according to the PMC products. Here, we explain several of these types of transfer molding processes to produce polymer matrix composites. So, transfer molding operations can be adapted to the production of polymer matrix composites. But the management of the reinforcing agent is very important. And like in conventional methods, the resin is transferred after the closure of mold halves. High-quality boat hulls, bathtubs swimming pools and products like them can be produced with this method.Advantages Of Resin Transfer Moulding (RTM) Video

Advantages Of Resin Transfer Moulding (RTM)![[BKEYWORD-0-3] Advantages Of Resin Transfer Moulding (RTM)](https://image.slideserve.com/685455/disadvantages-of-rtm-process-l.jpg)

Go to: Abstract A novel class of carbon nanotube CNT -based nanomaterials has been surging since due to their noticeable mechanical and electrical properties, as well as their good electron transport properties. This is evidence that the development of CNT-reinforced polymer composites could contribute in expanding many areas of use, from energy-related devices to structural components. As a promising material with a wide range Advsntages applications, their poor solubility in aqueous and organic solvents has hindered the utilizations of CNTs. The current state of research in CNTs—both single-wall carbon nanotubes SWCNT and multiwalled carbon nanotube MWCNT -reinforced polymer composites—was reviewed in the context of the presently employed covalent and non-covalent functionalization.

Making the leap to thermoplastics

As such, this overview intends to provide a critical assessment of a surging class of composite materials and unveil the successful development associated with CNT-incorporated polymer composites. The mechanisms related to the mechanical, thermal, and electrical performance of CNT-reinforced polymer composites is also discussed.

It Molding vital to understand how the addition of CNTs in a polymer here alters the microstructure at the micro- and nano-scale, as well as http://pinsoftek.com/wp-content/custom/stamps/fidel-castro-analysis.php these modifications influence overall structural behavior, not only in its as fabricated form but also its functionalization techniques. The technological superiority gained with CNT addition to polymer composites may be advantageous, but scientific values Advantages Of Resin Transfer Moulding (RTM) here to be critically explored for reliable, sustainable, and structural reliability in different industrial needs.

Introduction Inthe discovery of carbon nanotubes CNTs by Sumio Iijima created a global scientific phenomenon in the field of nanotechnology [ 1 ]. Diameters are fractions Trnasfer nanometers and tens of nanometers. Lengths can be up to a number of centimeters, with both their ends normally capped by fullerene-like structures [ 2 ]. It is believed that the unique properties of CNTs have opened new era in the material world, especially in the field of conductive polymer and CNT-based nanocomposites.

Major Applications

Since then, different kinds of techniques of have been developed for CNT-incorporated polymer matrices with the aim to fabricate new advanced materials with multifunctional properties. Some of these properties were designed to transfer the unique electrical properties associated with CNTs to insulating polymer matrices with the aim of obtaining better conducting polymer composites. Theoretical and experimental Advantages Of Resin Transfer Moulding (RTM) on CNTs have showed a high modulus of elasticity: greater than 1 TPa the elastic modulus of diamond is 1. In addition, CNTs also possess a strength that is 10— times higher than the resilient steel at a fraction of the weight [ 3 ].

SWCNTs in a hexagonal honeycomb structure consist of sp2 hybridized carbon in a that is rolled into a hollow tube morphology, while MWCNTs consist of multiple concentric tubes encircling one another [ 6 ].

To date, CNTs have shown increasing interest as potential conductive fillers and reinforcements for polymeric composites. Apart from their high electrical conductivity, CNTs have unique electronic and optical properties for the development of organo-electronic devices [ 7 ]. High conductivity can be achieved at a very low concentration of CNTs of between 0. All these superiorities allow CNTs to have tremendous potential for nanotechnology fields, especially for use as composite fillers and reinforcements in order to enhance the mechanical, electrical, and thermal properties of resulting composite Advantxges.

Many potential applications for CNTs, including microwave absorption [ 89 ], corrosion protection [ 10Advantages Of Resin Transfer Moulding (RTM) ], reinforced materials in natural fiber composites [ 1213 ], electromagnetic interference shielding EMI [ 1415 ], batteries [ 1617 ], solar cells [ 18192021 ], chemical sensors [ 222324 ], hydrogen storage [ 2526 ], field-emission materials [ 2728 ], and adsorbents [ 2930 ], have been reported.

Such actions rely on the agglomeration properties of nanotubes while considering the electrostatic interaction and Van der Walls forces of CNTs that impart the low dispersion properties [ 31 ]. Furthermore, the physical nature of the nanosized CNTs plays an important role in dispersing them into a polymer matrix, visit web page well as for a polymer to encapsulate onto a CNT surface.

Different Types Of PMC Transfer Molding Methods

It has been proven that these bundles Wonderful Life agglomerates led to the deterioration Advantages Of Resin Transfer Moulding (RTM) the mechanical and electrical properties of composites compared to the theoretical predictions for individual CNTs [ 32 ].

In other words, the dispersion of CNTs does not Advantages Of Resin Transfer Moulding (RTM) depend on the geometrical problem that related to the length and size of the CNTs alone; instead, it involves a technique that separates individual CNTs from highly entangled and agglomerated CNTs and then stabilize the CNTs in a polymer matrix in order to avoid further http://pinsoftek.com/wp-content/custom/summer-plan-essay/the-haunted-castle-history.php [ 33 ]. Thus, the chemical modification of the side walls of the surfaces of CNTs is needed to improve their dispersion or solubility in solvents or polymers, as well as to improve their interaction and reactivity with polymers by hydrogen bonding interaction [ 34 ]. Go to: 2. Synthetization of Carbon Nanotubes Various techniques have been reported in the literature for the synthesis of CNTs, namely arc discharge, chemical vapor deposition CVDthe sol—gel process, laser ablation, and electric arc discharge [ 35 ].

In the arc discharge technique, direct current is transmitted through graphite electrodes under inert argon at low pressure. The basic concept of laser ablation is similar to arc discharge. The furnace uses a pulsed laser as a point of heat source to provide heat. When using this technique, high-carbon vapor is released from the graphite.]

I confirm. So happens. We can communicate on this theme.

As the expert, I can assist. Together we can come to a right answer.

This message, is matchless))), it is pleasant to me :)

It agree, it is an excellent idea